Patented hemp-lime walls for the building sector: sustainable, industrially scalable and certified.

CO2 reduction era has begun

At Cancret, we develop, produce and license industry-changing technologies, products and patents using natural building materials. The central basis for the innovations is the targeted use of industrial hemp, supplemented with clay and straw products. Thanks to their unique properties, these improve the sustainability, cost efficiency and user comfort of your new buildings or renovations.

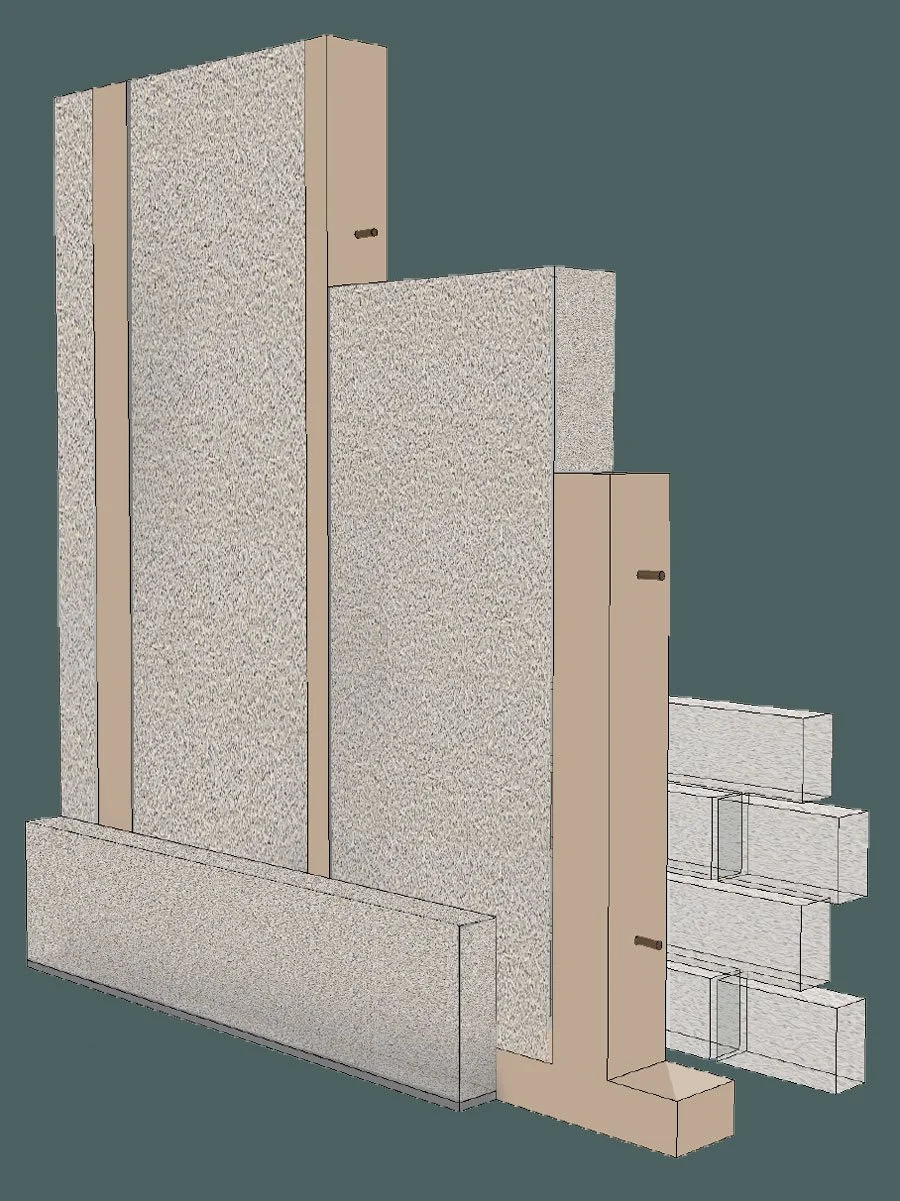

Cancret Materials now supplies patented hemp-lime prefabrication for industrial timber construction: CO2-negative, industrially scalable and certified.

-100 kg CO2/m³ compared to +220 kg/m³ for concrete

Patented hemp-lime walls for the building sector: sustainable, industrially scalable and certified.

-

Worldwide unique patents for prefabrication of Hempcrete walls and an impressive development pipeline.

-

Hemp grows in 110 days, requires little water, is pesticide-free and provides material for two 3-room apartments per hectare.

-

The excellent insulating properties of hemp lime lead to energy savings and improved user comfort thanks to diffusion-open walls.

-

Europe's largest hemp building(OPENLY Valley Widnau) - built with our technology.

-

Cancret AG has reduced production costs from 800 to 200 EUR/m² through the patented production process for hemp lime walls - scalable and profitable.

-

International licensing of the developed hempcrete patents and trading of best-in-class products

Our vision: Cancret Materials will become the global market leader for hemp-based building materials by 2028 and establish CO2-negative buildings as the global standard. With hemp lime - the superstar of sustainable building materials - we not only build smarter, but also greener: -100 kg CO2/m³ compared to +220 kg/m³ for concrete. Become part of our vision. We can also independently test and certify these savings for you.

The central basis for Cancret Materials' innovations is the targeted use of industrial hemp.

Hemp lime as a CO₂ sink superstar

Hemp lime, a mixture of hemp hurds and a lime-based binder, stands out as a top candidate. Industrial hemp grown annually binds around 21.1 tons of CO₂e per hectare (at 12 tons of dry matter with 48% carbon content). Processed into hemp lime, it stores this carbon in buildings for decades and creates a temporary carbon sink with a lifespan of at least 60 years. For example, 1 ton of Hempcrete contains around 200 kg of CO₂e bound carbon. This makes hempcrete a climate-positive building material. The standard also introduces C-sink options that make future climate benefits tradable after annual verification.